by Christopher Naughton

Innovate, Integrate and Improve.

Apple’s newest iPads utilize servo motors and facial recognition software to adjust the digital sensor of the camera and center you in the frame. This is a recreation of that mechatronic system…

The foot pressure mapping system measures an individual’s front and back foot loading. With data analysis, IoT connectivity, and an additional foot monitor, it proactively alerts users to any disparities in foot pressure over time. This feedback acts to reduce the risk of accelerated irregular weakening of healthy joints.

Using NI DAQ, a FLIR camera, and thermocouples attached to an MCU, we monitored a heated homogeneous egg mixture, uncovering a significant issue with phase changes. This insight can inform strategies to optimize heat transfer in electronic devices.

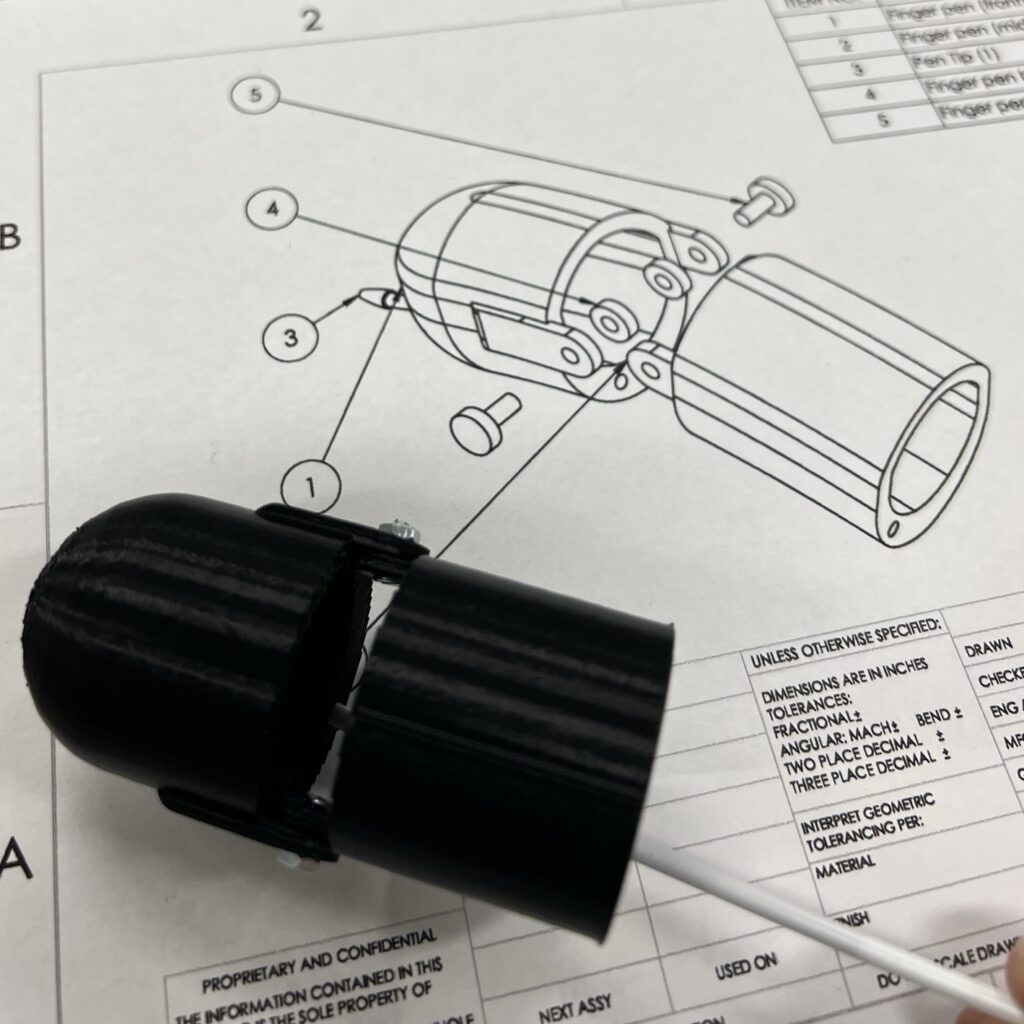

This device was designed to offer a comfortable, touch-screen-like writing experience to individuals who may be facing challenges due to missing appendages, joint related chronic diseases, or low grip strength.

Restoring a 1965 Ford Mustang Coupe (Windsor V8, 289 cu. (4.7 L) engine, two-barrel carburetor with ratio of 9:3:1 (C-Code)) are some of my fondest memories. The Mustang’s sporty design and performance laid the foundation for a legendary line of American muscle cars filled with innovation and heart. I am grateful to have worked on this car.

Tore a part a refrigerator to better understand heat pump cycles and the manipulation of refrigerant through pressure. The compressor pressurizes refrigerant, which moves through the condenser, expansion valve, and evaporator, absorbing heat from the interior and expelling it to the surroundings. We designed a PID controller to enhance temperature control by dynamically adjusting the compressor via error feedback from two thermocouples, minimizing fluctuations and optimizing efficiency.